Your designs for precision parts reach the limits of manufacturability?

Part design choices are typically governed by functionally required materials and manufacturability considerations. However, not all materials can be processed with all fabrication methods. This is especially true for the material choices in precision- and micro-AM, the fabrication method that gives the highest geometrical design freedom. Tradeoffs in part lay out, fabrication methods, and material selection are required. Additionally, economical and ecological considerations must be taken into account. Unlimited design freedom in part shape and materials, however, would allow radically new solutions and enable parts with, for example, higher miniaturization, functional integration, better performance, or reduced size, weight and power consumption.

3D coating processes for more functionality and material options in 3D microfabrication

Horizon Microtechnologies (HMT) removes or significantly eases such manufacturability issues by expanding the possible combinations of structuring approaches and materials available in micro-AM and 3D microfabrication. Our ultimate mission is to provide our customers with exactly the precision- and microparts they require.

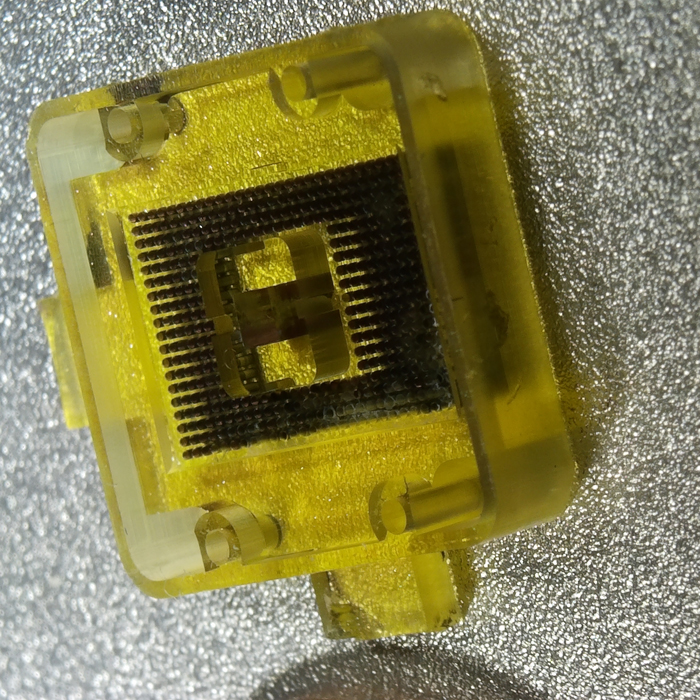

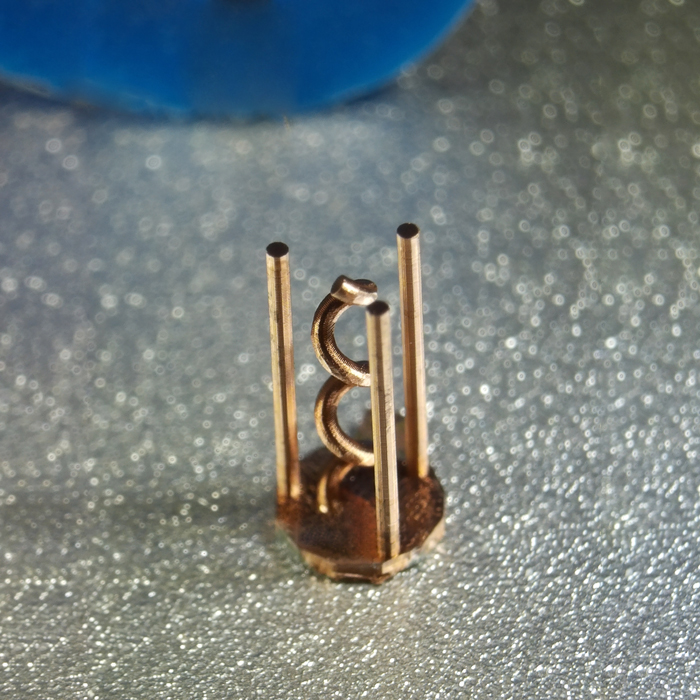

To do this, we have brought 3D microprinting capabilities in-house and have developed processes for coating parts in copper, ceramic-like metal oxide based protective coatings, and transparent conductive coatings. These coatings can be applied precisely onto parts of virtually any shape, and can be applied selectively to specific part areas. The coating processes are developed to work with 3D-printing / micro AM derived photopolymer parts, but can also be applied to a wide range of other materials and parts provided by our customers using other micro-fabrication technologies. Additionally, we can support our customers’ development efforts in designing functional parts best suited to our in-house 3D micro-printing and coating capabilities.